Polymers, Bio-Polymers, and composites have undeniable need and importance in our daily lives as they our the basic building block for almost everything use. these materials have been used in almost everything we touch such as consumer products, packaging, electric and electronic goods, furniture, automotive, aerospace, marine, construction, energy storage and generation to high-end medical and military applications.

The most used synthetic polymers are polyethene (PE), polyethylene terephthalate (PET), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), nylon, engineering plastics such as ABS, polycarbonate (PC), etc. These thermoplastics can be recycled and re-used, which is great for the environment. Selection of a specific polymer depends on the applications in which it supposed to be used and can meet product and performance requirements. Main source for the most synthetic polymers is petroleum crude feedstock.

Bio or natural polymers are produced from animals, plants, trees, and micro-organisms. They are generally classified into three categories: polysaccharides, polynucleotides, and polypeptides. The most common used ones are PLA (polylactic acid), starch, cellulose, rapeseed protein, gelatin, natural rubber, lignin, peptides, etc. These polymers are biodegradable.

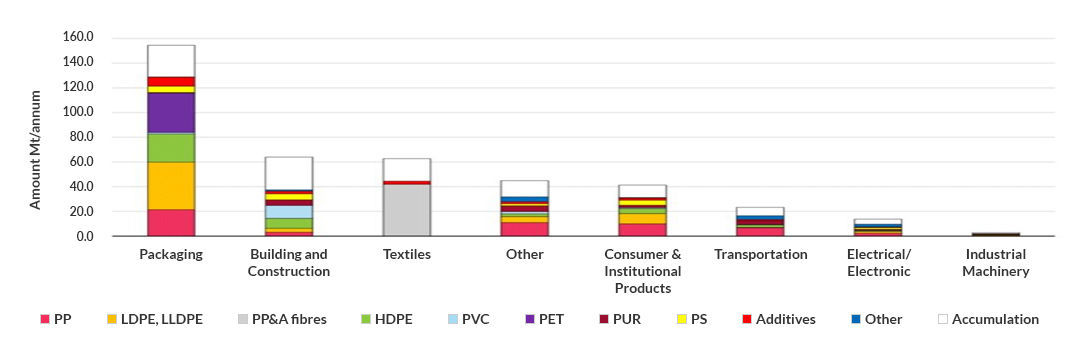

Market trend of various polymers and biopolymers are increasing rapidly due to the high demand in various industrial and consumer sectors such as automobile industry, marine industries, aerospace industries, chemical industry, disposable and non-disposable consumer goods, construction industries, structural metal and alloy replacement, electrical and electronic goods, medical goods, energy storage and production sectors, etc. Fig 1 shows annual consumption of polymers in various applications.

Between 2020 and 2025, the global commodity polymers market is expected to expand at a CAGR of 6.0%, from USD 468.3 billion in 2020 to USD 596.1 billion in 2025.

The worldwide biopolymers market was estimated at US 9131.9 million in 2018 and is projected to grow at a CAGR of 13.8% in revenue from 2019 to 2027, reaching US 28,101.7 million.

Almost all synthetic polymers are processed and manufactured from petroleum crude feedstocks. Many complex processes, equipment, and activators (catalyst) are involved in the synthesis and commercial production process. Most commercial biopolymers are produced from plant-based resources and processed using various chemical treatments. Each polymer is produced via polymerization process from its basic structural unit called monomer, in which monomer molecules are chemically bonded to get large polymer molecules, call polymer.

The injection molding process is similar to thermoplastic materials just the addition of crosslinking agents during the molding operation.

In this process, the material is heated, melted, and shaped after material charging in the mold.

The fabric material passed through a polymer resin bath before getting a shape and then heated for the curing process.

A polymer resin material is spread over the fabric material on mold halves then heated, and pressurized to attain the desired shape.